Ultrasonic Nozzle Vibration Machine

Custom Model

● Efficient Material Separation:

Effectively separates hard materials such as ABS, AC, PC, ABS+PC porcelain steel, and fiberglass, while being unsuitable for soft materials like PE and PVC.

●Versatile Applications:

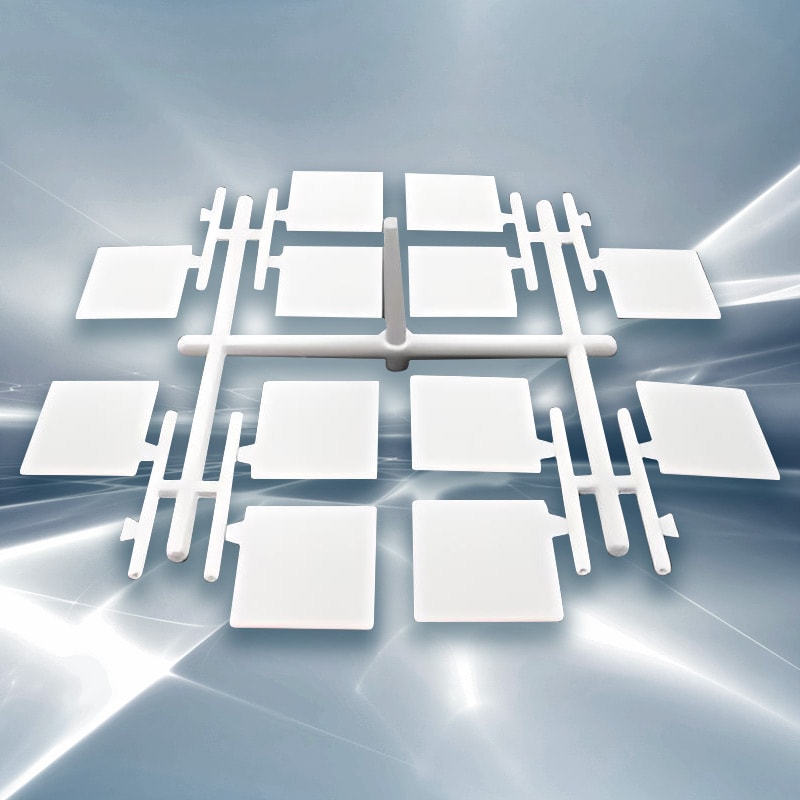

Ideal for processing electronic product buttons, rivets, watches, and other small plastic accessories, with a nozzle size of ≤150x100mm.

● Enhanced Discharge Control:

Features a reduced discharge port to ensure more concentrated discharge, improving overall efficiency during the separation process.

● Simplified Operation:

The redesigned mold adjustment area allows for easier operation, while the increased height of the inclined platform ensures smoother discharge and operation.

● Reliable and Durable Components:

Assembled with high-quality imported electrical components and alloy steel variable spoke rods, providing strong, stable sound waves and guaranteeing the system doesn't overheat.

Request for Quote- Features |

- Certification |

- Packaging |

- Reviews

Ultrasonic Nozzle Vibration Machine Features

The machine employs high-frequency vibrations to separate gates from products at their connection points. This precise and efficient method ensures no damage to the product.

The ultrasonic nozzle vibration machine operation is straightforward, following a simple process of equipment inspection, mold installation and verification, and machine operation. Users can adjust vibration amplitude based on product size to achieve optimal separation.

Full automation: The machine performs gate separation automatically, enhancing production efficiency while minimizing manual intervention.

High adaptability: Compatible with various materials including plastics, zinc alloys, and aluminum alloys across different specifications.

Excellent separation results: Gates are removed cleanly, leaving smooth, flat surfaces without whitening—enhancing both product quality and appearance.

Ultrasonic nozzle vibration machines serve diverse industries, including post-injection molding, food processing, pharmaceuticals, chemical manufacturing, and wastewater treatment.

We are Internationally Certified

Our ultrasonic nozzle vibration machine are certificated with CE,ISO and ROSH. They all meet international standards.

Packaging for Ultrasonic Nozzle Vibration Machine

Customer Reviews

Quote Now

Quote Now